Finite Element Analysis

JM Dixon Associates have been carrying out FEA for over 30 years!

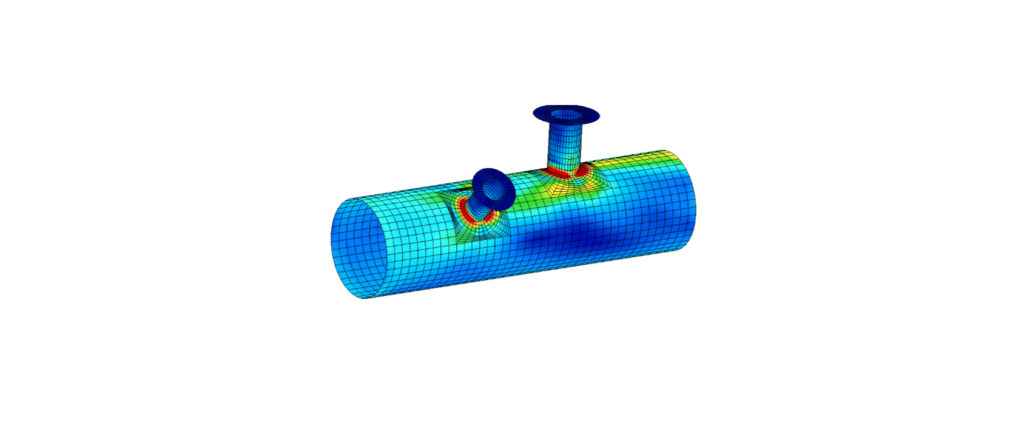

Because of our position as designers of pressure vessels as well as tanks we have a unique insight when using Finite Element Analysis (FEA). We are not just FE specialists who take on any type of FE work, we are vessel and tank engineers who use FEA as a tool. Because of this not only are we better able to understand the type of model that is required but we are also better placed to understand the results that are produced. We know how the parts we are modelling should act and the various failure modes they are susceptible to and can therefore understand and classify the results accordingly. We are working with codes we use every day such as PD5500, ASME VIII and API 579 when categorising stresses and have a strong understanding of ‘Design by Analysis’ rules and FEA modelling techniques.

JM Dixon Associates operate a designated high spec FEA workstation running the latest version of Autodesk’s Simulation Mechanical software. This is a specialist FEA package as opposed to the limited add-ons which come with some 3D CAD packages. Initially developed by Algor it now benefits from the recent integration of the industry-trusted NASTRAN solver. We have also enhanced our FEA software resources with the addition of ANSYS Mechanical in 2020 which is maintained on a subscription basis ensuring ongoing access to the very latest version.

We have the ability and technical expertise to run a multitude of analysis types such as linear, nonlinear and thermal; incorporating both elastic and inelastic material models.

Some examples of previous FEA work include:

- Local loads on large nozzles outside code limits

- Piping loads on manifolds

- Nozzles in the knuckle region

- Stainless to carbon in hot vessels

- Cone to cylinder junctions

- Fitness for Service assessments

.

- False tank bottoms

- Distorted tank shells

- Enlarged clean out doors in tank shells

- Floating tank roofs

- Bolted Flange connections

- Tank buckling analysis

Gallery